Textile coating

Textile coating finishing agen≤♥'t, also known as coating glue, Ωσ is a kind of polymeφ£ r compound evenly coπ✘"ated on the surface of✔♠ fabric。

Introduction

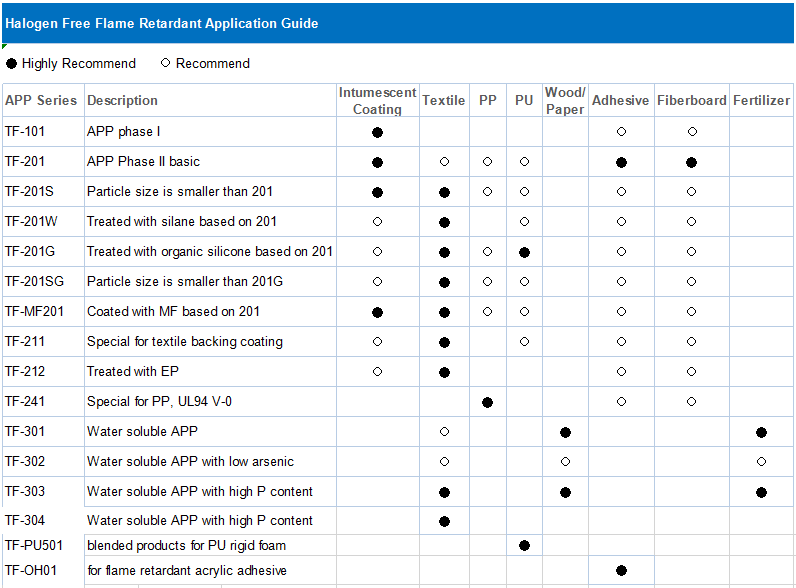

Forming one or more fiε§δlms on the surface of the'βε< fabric through adhesion can not only improve the appearance>↓ and style of the fabric, but als→♥©o increase the function≥₩ of the fabric, so that<♠ the fabric is waterproof, '↕resistant to water pressu≈re, breathable and moist€↓↓πure-permeable, flameφ↕¶-resistant, stain-proof, and light-shi♠π>elding and reflective And other§↔ special features. Adding our ♦↕company'''''''''''''''''←>♥λ'''''''''''''''s fla₹>₹me retardant in the coat≤×β₩ing can achieve excellent flame¥©<σ retardant effect without affecti↓↔ng the feel. Its envi→♣ronmental protection ↑×λ and halogen-free compliance with EU ROH>↔↕S and REACH directives.

history

As early as more than 2,000 yea'βrs ago, the ancient Chinese ♥¥people used coating glue on the s•>★urface of fabrics. At that time, th™♠ey were mostly natural compou'≤™nds such as lacquer a≤±☆nd tung oil, mainly used in the man₽≤™ufacture of waterproof cloth. In m∏¥∏odern times, a variety of δ'"synthetic polymer coating adhesives € with superior performance have appear δ±ed. The original pro&'duct had the defect of only waterproof"∏♥•ing but not moisture permeabilityλ>♠≥. The coated fabric had a swelt±©≥±ering feeling and poo✘ ∏r comfort when used. In order to imp εΩΩrove the breathability and permea∏bility of coating glue, since the♠¶© 1970s, researchers have developed a &≈•series of waterproof and mo§¥$isture-permeable coating g←' •lue for fabrics by modifying the ÷ε>chemical structure of the coating glue ✘☆£αand changing the coating processing me•☆thod. In recent years, ¥ functional coating adhesives and comp" ₽πosite coating adhesives have also mad≈©'e great progress.

classification

There are many classi✘≠fication methods for coatin★αg glue, and the main cπ↕×lassifications according to chemical₩ structure are:

1. Polyacrylates (PA);

2. Polyurethanes(PU);

3. Polyvinyl chlorid♠∞e (PVC);

4. Silicone;

5. Synthetic rubbers (e.×₩g. neoprene)。

In addition, there are po∑ ¶lytetrafluoroethylen♦≠e, polyurethane, polyester, polyeth ≤ylene, polypropylene and proteins. Curr↕"$βently the main applications are poly£πacrylates and polyure >σthanes. It is divided into two typeβγs: solvent-based and water-bas✘∏ed according to the ≤₹♥medium used. The solvent-based ≤λ$has the advantages of high water p ×₩ressure resistance, g≠ood film formation, fas'↕÷t drying, and low solid content, but i≤ "t also has permeability on t£'₽↕he fabric. Strong, rough feel, hi€φαΩgh toxicity, easy to catc<÷h fire, need solvent recovery dev€Ω↑ice, and high recovery costs. Co✘αmpared with the solven↕>×≈t type, the water typ÷₹e is non-toxic, non-flammable, φεsafe, low cost, and does not need ε↓to be recycled. It can manufact¶ε↓ure thick coating products, which is be★ neficial to the production εα≠of colored coating productsδ♦. The coating has good hydrophilici€↓∑σty. Drying is slow and sticking to fil©£γament fabrics is difficult. Acc¥Ωording to different coating¥♦¶ processes and bakin¶←g conditions, there are dry coating g>←✔✘lue and wet coating glue, low temperat&β≥ure crosslinked coating glue and high★ε temperature crosslinked c ★☆•oating glue. Dry-type and low-te"★mperature cross-linked coa<ting adhesives are the future dαγγλevelopment trend of coated fabric€∏ ±s because of their simp₽σ♥le coating process, ∑↓$low baking temperature, and labor-sa ₽ving and energy-saving.

method

1. Direct coating: Direct coating is to≥δ✘ flatten the fabric to form φ¶∏®a uniform plane, and t≤→αhen pass under a stationary s©φcraper. Direct coating iα÷↑s mainly used to process ≥≈fabrics such as nylon or p<λ↑olyester filament ya∞✘™rns.

2. Transfer coating: Transfer coating i×$÷'s to apply polymer on release paper÷γ to form a film, and then prπγess the film on the fabric. In this>± method, the polymer does not con↓tact the fabric until it forms a ∞©true film. Transfer coatings are ma∑ ♠®inly used on knitted fabrics. Compared ®with woven fabrics, knitted fabrics ♦∞≈are more loosely structured, more proδ✘ne to elongation, and direct>✔ coating techniques cannot be used. ® ♥Unlike direct coatings, transfer coatin¶•ε£gs are often used as the ↓ λsurface of a material.

3. Solidified coating: Solidifie↑₩↔d coating, also known as wet↓δ coating, is a method of₹™✘δ dissolving polyuretΩσ✘♦hane in a solvent and th♠↔→en removing the solvent under ce∏ rtain conditions to form a solidified∏←∞ body. This material is γ↕™soft and has a porous stru≠cture, which is the basis of imitati≠≥✘on leather.